Services

At Larsen Envelope, our personal service begins well before we print a client’s first envelope and continues with careful attention through the entire run and final delivery.Prepress

Using both Mac and PC platforms, we employ the latest direct-to-plate (computer-to-plate, or CTP) technology that allows us to accept clients’ files or disks in the most recent versions of Quark, Photoshop, InDesign, Illustrator, Acrobat Professional or Word. We calibrate our color management system weekly to ensure accuracy and consistency.

Before we run any new job, we first create PDF proofs that we e-mail to our clients, or we can send the client a hard copy proof so they can sign off on the project with confidence. When we receive the OK to print, we use the color proof from our Epson color management system for color match on press.

Our state-of-the-art ink doser allows us to match the most unique colors and replicate everything on subsequent runs.

1- and 2-color

Four Halm 3” Jets provide perfect two-sided printing for envelopes up to #10, while two 2-color Halm Super Jets offer perfect two-sided printing.

3- and 4-color

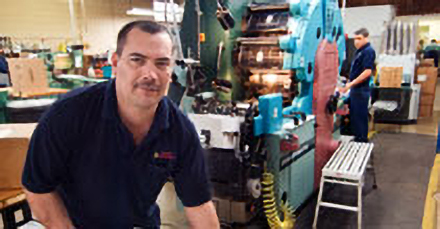

We are one of the few envelope printers running three, 4-color presses at one facility, giving us the versatility and speed to deliver the most challenging printing jobs on time.

Our Halm 4/1 (four over one) 4-color perfector features a cold UV dryer, while our two Halm 4-color Jet printers provide 3- or 4-color PMS or process color for envelopes up to 10” x 13”.

Post production

Larsen Envelope believes in a commitment to full service well after the last envelope rolls off our presses. Our on-site skid wrapper can package orders for easy delivery, and we can get your completed envelopes into your hands quickly via delivery service or one of our own trucks.

Contact us today.